In order to promote public education and public safety, equal justice for all, a better informed citizenry, the rule of law, world trade and world peace, this legal document is hereby made available on a noncommercial basis, as it is the right of all humans to know and speak the laws that govern them.

This Joint Australian/New Zealand Standard was prepared by Joint Technical Committee CH-026, Safety in Laboratories. It was approved on behalf of the Council of Standards Australia on 13 May 2010 and on behalf of the Council of Standards New Zealand on 27 August 2010. This Standard was published on 17 September 2010.

The following are represented on Committee CH-026:

Australian Industry Group

Australian Institute of Occupational Hygienists

CSIRO

Department of Labour, New Zealand

Department of Primary Industries, Vic.

Environmental Science and Research, New Zealand

Ministry of Agriculture and Forestry, New Zealand

Ministry of Economic Development, New Zealand

National Association of Testing Authorities, Australia

National Measurement Institute, Australia

New Zealand Chemical Industry Council

New Zealand Microbiological Society

RMIT University

Royal Australian Chemical Institute

WorkSafe Victoria

WorkCover New South Wales

Additional Interests:

Australasian Plant Pathology Society

Australian National University

Australian Quarantine and Inspection Service

Australian Society for Microbiology

Biosafety Consultant

Containment consultants

CSIRO, Division of Livestock Industries

Microbiologists

Office of The Gene Technology Regulator

Sterilizing Research Advisory Council of Australia, Vic.

Victorian Infectious Diseases Reference Laboratory

Keeping Standards up-to-date

Standards are living documents which reflect progress in science, technology and systems. To maintain their currency, all Standards are periodically reviewed, and new editions are published. Between editions, amendments may be issued. Standards may also be withdrawn. It is important that readers assure themselves they are using a current Standard, which should include any amendments which may have been published since the Standard was purchased.

Detailed information about joint Australian/New Zealand Standards can be found by visiting the Standards Web Shop at www.saiglobal.com.au or Standards New Zealand web site at www.standards.co.nz and looking up the relevant Standard in the on-line catalogue.

For more frequent listings or notification of revisions, amendments and withdrawals, Standards Australia and Standards New Zealand offer a number of update options. For information about these services, users should contact their respective national Standards organization.

We also welcome suggestions for improvement in our Standards, and especially encourage readers to notify us immediately of any apparent inaccuracies or ambiguities. Please address your comments to the Chief Executive of either Standards Australia or Standards New Zealand at the address shown on the back cover.

This Standard was issued in draft form for comment as DR 07335.

iiAS/NZS 2243.3:2010

Originated as AS 2243.3—1979.

Previous edition AS/NZS 2243.3:2002.

Sixth edition 2010.

COPYRIGHT

© Standards Australia Limited/Standards New Zealand

All rights are reserved. No part of this work may be reproduced or copied in any form or by any means, electronic or mechanical, including photocopying, without the written permission of the publisher, unless otherwise permitted under the Copyright Act 1968 (Australia) or the Copyright Act 1994 (New Zealand).

Jointly published by SAI Global Limited under licence from Standards Australia Limited, GPO Box 476, Sydney, NSW 2001 and by Standards New Zealand, Private Bag 2439, Wellington 6140

ISBN 978 0 7337 6996 2

1This Standard was prepared by the Joint Standards Australia/Standards New Zealand Committee CH-026, Safety in Laboratories, to supersede AS/NZS 2243.3:2002, Safety in laboratories, Part 3: Microbiological aspects and containment facilities.

Major changes in this edition are as follows:

The Committee is currently addressing the need to develop a section for containment of water based species, including fish and aquatic invertebrates. Some applicable information may be found in the laboratory and animal facility sections of this Standard.

The containment of plant pathogens is primarily concerned with minimizing hazards due to inadvertent spread to the environment. This is in contrast to the containment of human and animal pathogens, where the principal aim is to avoid risk of infection or contamination of facility workers and the community.

The containment of invertebrate pathogens may involve the minimization of hazards associated with inadvertent spread to the environment or microbiological hazards associated with exposure to people or animals. It may involve both of these hazards simultaneously. Where hazards to personnel are present in an invertebrate facility, the invertebrates and laboratory work will need to be carried out in a laboratory of appropriate microbiological containment level to protect the personnel, along with the additional containment features associated with invertebrate containment.

The Parts of the series promoting safety in laboratories are as follows:

| Part 1: | Planning and operational aspects |

| Part 2: | Chemical aspects |

| Part 3: | Microbiological safety and containment (this Part) |

| Part 4: | Ionizing radiations |

| Part 5: | Non-ionizing radiations—Electromagnetic, sound and ultrasound |

| Part 6: | Mechanical aspects |

| Part 7: | Electrical aspects |

| Part 8: | Fume cupboards |

| Part 9: | Recirculating fume cabinets |

| Part 10: | Storage of chemicals |

Although many of the safety aspects of working in laboratories are addressed in other Parts of the series, some are repeated here in Part 3 because there is an increase in the risk in containment facilities.

2This Standard is intended to cover safety and containment aspects of work with microorganisms, including genetically modified microorganisms. However, it does not cover the additional security requirement that may be implemented in response to community interest and concerns in genetic modification work. For these, the relevant regulatory authority should be consulted. Also, the Standard is not primarily intended to address containment of organisms for work that does not involve microorganisms.

This Standard is intended to assist in addressing the obligations placed on employers and employees under occupational health and safety legislation to take care of both themselves and others in the workplace. It should not be assumed that compliance with this Standard means that all aspects of appropriate legislation or all legal obligations are being fulfilled. This Standard is not intended to provide for compliance with a specific act or regulation.

It should be noted that nothing in this Standard is required by law in any jurisdiction unless the Standard has been specifically incorporated by an Act or regulation in that jurisdiction. The exact manner of incorporation will determine whether the whole document, or specific sections or provisions, are made legal requirements or whether the Standard becomes an Approved Code of Practice. However, it should also be noted that this Standard is recognized in common law as defining current knowledge in microbiological safety practice. The provisions in a Code are not mandatory but give practical guidance on how to comply with the relevant provisions of the Act or regulation. Provided an alternative method also fulfils the requirements of the Act or regulation, it may be used. Users will need to consult the relevant authority to determine if this Standard has been incorporated and the manner of incorporation, if any.

In recognition of the changes made to this Standard during its revision, existing facilities should be assessed for risk and interim control measures should be implemented.

Current facilities and procedures should be updated to conform to this Standard. Compliance improvements should be made within a time frame that takes into consideration the cost of upgrading and the severity of the associated risk.

The terms ‘normative’ and ‘informative’ have been used in this Standard to define the application of the appendix to which they apply. A ‘normative’ appendix is an integral part of a Standard and contains requirements that have to be met for compliance with the objectives and intent of this Standard. An ‘informative’ appendix is only for information and guidance.

3| Page | ||

| FOREWORD | 7 | |

| SECTION 1 SCOPE AND GENERAL | ||

| 1.1 | SCOPE | 8 |

| 1.2 | OBJECTIVE | 8 |

| 1.3 | REFERENCED DOCUMENTS | 8 |

| 1.4 | DEFINITIONS | 8 |

| 1.5 | ABBREVIATIONS | 12 |

| SECTION 2 ORGANIZATION AND RESPONSIBILITY | ||

| 2.1 | RESPONSIBILITY | 13 |

| 2.2 | QUARANTINE MATERIALS | 14 |

| 2.3 | LABORATORIES USING GENETICALLY MODIFIED ORGANISMS (GMOs) | 15 |

| 2.4 | LABORATORY BIOSECURITY | 16 |

| 2.5 | COMMISSIONING | 16 |

| 2.6 | HEALTH MANAGEMENT | 16 |

| 2.7 | INCIDENT REPORTING | 18 |

| 2.8 | EMERGENCY RESPONSE AND CONTINGENCY PLANS | 18 |

| SECTION 3 DEGREE OF HAZARD FROM MICROORGANISMS | ||

| 3.1 | GENERAL | 19 |

| 3.2 | CLASSIFICATION OF MICROORGANISMS BY RISK GROUP | 20 |

| 3.3 | RISK-GROUPING OF MICROORGANISMS BY TYPE | 22 |

| 3.4 | HUMAN AND ANIMAL CLINICAL AND DIAGNOSTIC SPECIMENS | 23 |

| 3.5 | QUALITY ASSURANCE OF CULTURES AND MATERIALS | 23 |

| 3.6 | WORK WITH HUMAN, ANIMAL OR PLANT CELLS | 24 |

| 3.7 | PRIONS | 24 |

| SECTION 4 PRINCIPLES OF CONTAINMENT | ||

| 4.1 | GENERAL | 35 |

| 4.2 | CONTAINMENT MEASURES | 35 |

| 4.3 | PHYSICAL CONTAINMENT CLASSIFICATIONS | 36 |

| 4.4 | LOCATION | 37 |

| SECTION 5 LABORATORY CONTAINMENT FACILITIES | ||

| 5.1 | LABORATORY PHYSICAL CONTAINMENT | 38 |

| 5.2 | REQUIREMENTS FOR PC1 LABORATORIES | 38 |

| 5.3 | REQUIREMENTS FOR PC2 LABORATORIES | 40 |

| 5.4 | REQUIREMENTS FOR PC3 LABORATORIES | 44 |

| 5.5 | REQUIREMENTS FOR PC4 LABORATORIES | 49 |

| SECTION 6 ANIMAL CONTAINMENT FACILITIES | ||

| 6.1 | REQUIREMENT FOR ANIMAL CONTAINMENT FACILITIES | 55 |

| 6.2 | PRINCIPLES OF ANIMAL CONTAINMENT | 55 |

| 6.3 | OTHER CONSIDERATIONS ASSOCIATED WITH ANIMAL CONTAINMENT | 56 |

| 6.4 | REQUIREMENTS FOR ANIMAL PC1 FACILITIES | 58 |

| 6.5 | REQUIREMENTS FOR ANIMAL PC2 FACILITIES | 60 |

| 6.6 | REQUIREMENTS FOR ANIMAL PC3 FACILITIES | 63 |

| 6.7 | REQUIREMENTS FOR ANIMAL PC4 FACILITIES | 69 4 |

| SECTION 7 PLANT CONTAINMENT FACILITIES | ||

| 7.1 | GENERAL | 75 |

| 7.2 | REQUIREMENTS FOR PLANT PC 1 FACILITIES | 75 |

| 7.3 | REQUIREMENTS FOR PLANT PC2 FACILITIES | 76 |

| 7.4 | REQUIREMENTS FOR PLANT PC3 FACILITIES | 79 |

| 7.5 | REQUIREMENTS FOR PLANT PC4 FACILITIES | 86 |

| SECTION 8 INVERTEBRATE CONTAINMENT FACILITIES | ||

| 8.1 | GENERAL | 90 |

| 8.2 | REQUIREMENTS FOR INVERTEBRATE PCI FACILITIES | 90 |

| 8.3 | REQUIREMENTS FOR INVERTEBRATE PC2 FACILITIES | 92 |

| 8.4 | REQUIREMENTS FOR INVERTEBRATE PC3 FACILITIES | 95 |

| 8.5 | REQUIREMENTS FOR INVERTEBRATE PC4 FACILITIES | 101 |

| SECTION 9 MICROBIOLOGICAL SPILLS | ||

| 9.1 | GENERAL | 106 |

| 9.2 | PLANNING | 106 |

| 9.3 | SPILLS INSIDE BIOLOGICAL SAFETY CABINETS | 107 |

| 9.4 | SPILLS OUTSIDE BIOLOGICAL SAFETY CABINETS | 108 |

| 9.5 | CENTRIFUGE SPILLS | 112 |

| SECTION 10 CHEMICALS, PPE AND SPECIAL EQUIPMENT | ||

| 10.1 | CHEMICALS | 114 |

| 10.2 | PERSONAL PROTECTIVE EQUIPMENT (PPE) | 114 |

| 10.3 | CENTRIFUGES | 116 |

| 10.4 | FREEZE-DRYING AND RECONSTITUTION OF CULTURES | 117 |

| 10.5 | LIQUID NITROGEN | 118 |

| 10.6 | PRESSURE STEAM STERILIZERS | 119 |

| 10.7 | BIOLOGICAL SAFETY CABINETS | 122 |

| 10.8 | LAMINAR FLOW CYTOTOXIC DRUG SAFETY CABINETS | 123 |

| 10.9 | HEPA FILTERS | 123 |

| SECTION 11 CLEANING | ||

| 11.1 | GENERAL | 125 |

| 11.2 | CLEANING PERSONNEL | 125 |

| 11.3 | CLEANING OF EQUIPMENT | 125 |

| 11.4 | WALLS AND SHELVES | 125 |

| 11.5 | FLOOR CLEANING | 125 |

| SECTION 12 CONTAMINATED MATERIALS AND WASTE | ||

| 12.1 | COLLECTION | 127 |

| 12.2 | DECONTAMINATION AND DISPOSAL OF WASTES | 127 |

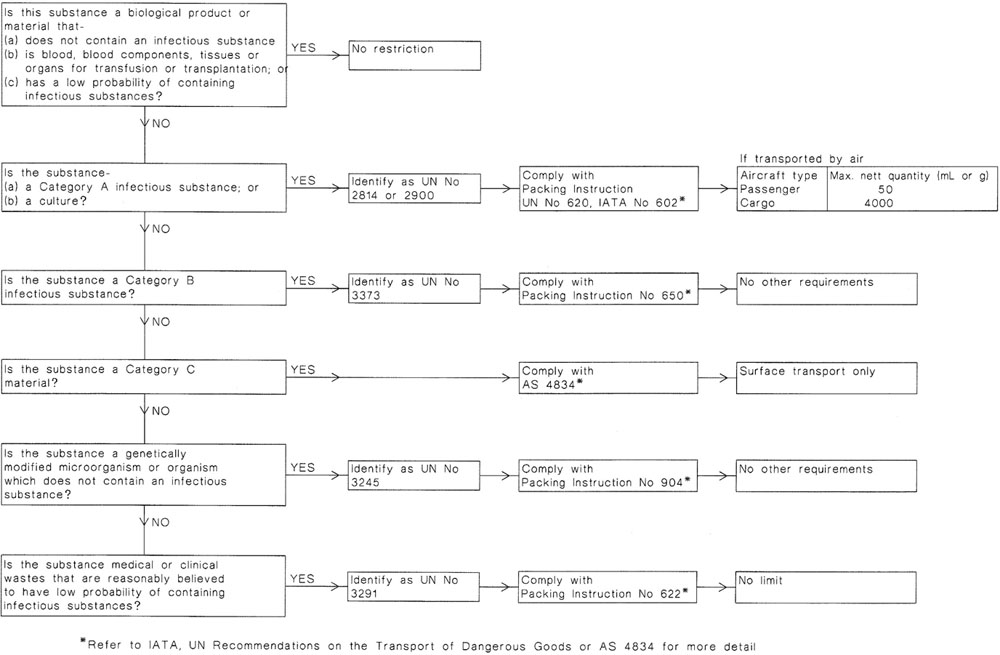

| SECTION 13 TRANSPORT OF INFECTIOUS AND OTHER BIOLOGICAL MATERIALS | ||

| 13.1 | GENERAL | 130 |

| 13.2 | TRANSPORT REGULATIONS | 130 |

| 13.3 | TRANSPORT DEFINITIONS OF BIOLOGICAL MATERIALS | 131 |

| 13.4 | CLASSIFICATION AND PACKAGING | 131 |

| 13.5 | TRANSPORT OF INFECTED ANIMALS | 135 |

| 13.6 | DOCUMENTATION | 135 5 |

| APPENDICES | ||

| A | REFERENCED AND RELATED DOCUMENTS | 138 |

| B | EXAMPLE MICROBIOLOGICAL INCIDENT/ILLNESS REPORT FORM | 144 |

| C | ADDITIONAL CONTAINMENT REQUIREMENTS FOR POLIOVIRUS | 145 |

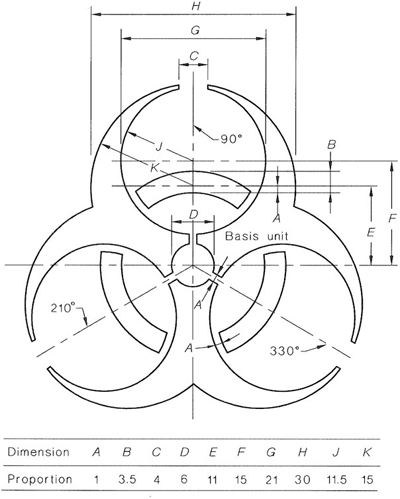

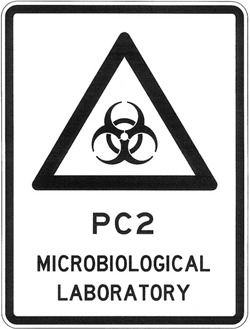

| D | BIOLOGICAL HAZARD SIGNS | 147 |

| E | WATER AND GAS SUPPLIES TO CONTAINMENT FACILITIES | 149 |

| F | CHEMICAL DISINFECTANTS | 153 |

| G | EXAMPLES OF RECOMMENDED LAYOUTS FOR PC3 AND PC4 FACILITIES | 164 |

| H | RECOMMENDATIONS ON ACCEPTABLE ROOM AIRTIGHTNESS | 169 |

Safety in all laboratories is primarily a management responsibility, but is also an individual responsibility. It is the responsibility of management to provide and maintain protective equipment and containment areas, a policy relating to safe work practices within a laboratory and to promote the training in, and institution of, those practices. It is the responsibility of the laboratory staff to carry out the safe work practices and to use protective equipment to minimize injury or prevent occupational illness, not only to themselves, but also to their colleagues. It is also a responsibility of managers to ensure that consideration is given to hazards to the general environment when dispensing or handling biological material. Staff training must be directed toward making safety an attitude of mind and an integral part of all laboratory procedures, so that a constant, purposeful control of the laboratory environment will result. Accidents such as spillages are an obvious hazard, but the production of aerosols during some routine procedures is a less obvious hazard that can be a serious source of contamination. In addition to the many problems commonly encountered in chemical laboratories, microbiological laboratories can pose the following specific problems:

The basic approach to working with microorganisms is to regard them as potential pathogens and to handle them with standard microbiological techniques. Nevertheless, microorganisms vary markedly in their pathogenicity. This Standard includes the classification of microorganisms into four risk groups and specifies work requirements for the corresponding four physical containment levels.

7STANDARDS AUSTRALAIA/STANDARDS NEW ZEALAND

Australian/New Zealand Standard

Safety in laboratories

Part 3: Microbiological safety and containment

This Standard sets out requirements, responsibilities and general guidelines relating to safe handling and containment of microorganisms and prions in laboratories. It includes animal, plant and invertebrate containment facilities (these may be integral or separate to the laboratory) where microbiological work such as research, teaching, diagnosis, quality control and regulatory analysis, e.g. of foodstuffs, water and effluents, pharmaceuticals and cosmetics, is undertaken. It may also provide assistance to other laboratories where specimens that may contain pathogenic microorganisms and prions are handled, e.g. biochemistry and soil laboratories. This Standard should be read in conjunction with AS/NZS 2243.1, AS/NZS 2982.1, building codes in Australia and New Zealand and other relevant Parts of the AS/NZS 2243 series.

NOTES:

The objective of this Standard is to provide management and staff of laboratories and containment facilities with requirements and guidelines that promote microbiological safety and prevent the unintended spread of microorganisms and prions.

Documents referred to in this Standard are listed in Appendix A.

For the purpose of this Standard, the definitions below apply.

Suspension in air of finely dispersed solids or liquids.

8NOTE: Any procedure that disrupts the surface of a liquid has potential to produce aerosols. Procedures such as shaking, mixing and ultrasonic disruption are particularly common examples for microbiological work.

A separate, fully-enclosable space with two doors designed to limit pressure fluctuations during entry and exit. A shower airlock is an airlock that incorporates full body shower capability, which can be used as part of exit procedures.

A separate, fully-enclosable space used during access and egress that has specific containment functions.

Substance capable of destroying or preventing growth of microorganisms under prescribed conditions of use, and specifically for application to living tissues.

The exercise of special procedures for maintaining—

The potential microbiological source of harm.

Cabinets intended to provide protection from hazardous biological agents for personnel and the environment. The cabinets are exhaust ventilated, with an inward flow of air away from the operator and high-efficiency particulate air (HEPA) filtration of exhaust air.

Cabinets intended to provide protection from hazardous biological agents for personnel and the environment and also to protect the material used in the cabinet from exogenous contamination. The cabinets provide this protection by inducing an inflow of air through the work access opening, by delivering recirculated, filtered, laminar flow air downwards through the work zone and by HEPA filtration of exhaust air.

Totally enclosed, ventilated cabinets that allow work to be performed through the use of attached gloves. These cabinets are gas-tight, maintained under a negative air pressure, have their supply air HEPA-filtered and have their exhaust air passed through two HEPA filters in series. Transfer boxes allow passage of materials into and out of the work zone while maintaining the negative pressure.

The containment principles, technologies and practices that are implemented to prevent the unintentional exposure to biological agents and toxins, or their accidental release.

A committee that provides advice, resources and facilities as are necessary for safe working in laboratories.

9NOTE: An institutional biosafety committee (IBC) is specific to gene technology. An institutional biological safety committee (IBSC) is the New Zealand equivalent of an IBC.

A separate, fully-enclosable space used by personnel for donning facility clothing and PPE on entry and for removing it on exit.

Space used by personnel to remove personal clothing as appropriate to facility level prior to entry and to don personal clothing on exit, e.g. from shower airlock.

A person who has acquired through training, qualifications or experience, or a combination of these, the knowledge and skills enabling that person to perform a specified task.

The combination of buildings, engineering function, equipment, and worker practices used to handle microorganisms and prions safely.

May comprise a combination of laboratories, animal, plant and invertebrate facilities and associated rooms within a physical containment barrier. This may include airlocks, access and support rooms and interconnecting corridors.

NOTE: This definition is distinct from that used in the MAF Biosecurity New Zealand and ERMA New Zealand Standard Facilities for Microorganisms and Cell Cultures: 2007a.

The undesirable transfer of microorganisms from one source to another.

A physical or chemical process that kills or removes pathogenic microorganisms, but does not necessarily result in sterility.

Any human, animal, plant or invertebrate material including, but not limited to, excreta, secreta, blood and its components, tissue and tissue fluids submitted for purposes of diagnosis or analysis.

A substance capable of killing a wide range of microorganisms; its use is usually confined to hard surfaces.

The airborne concentration of a particular substance (not microorganisms) in the worker’s breathing zone, exposure to which, according to current knowledge, should not cause adverse health effects nor cause undue discomfort to nearly all workers. The exposure standard can be of three forms; time-weighted average (TWA), peak limitation, or short term exposure limit (STEL).

A ‘high-efficiency particulate air’ (HEPA) filter complying with the requirements in Clause 10.9.1.

A microorganism capable of invading a susceptible host and multiplying in it, which may or may not cause a disease.

10Includes all multi-cellular animal species without backbones that are land based as adults. This includes annelids, cnidarians, echinoderms, flatworms, nematodes, molluscs and arthropods. Protozoans are not included due to their microscopic size and single cellular nature.

The potential microbiological source of harm, often called a ‘biohazard’.

An incident where control of infectious material has been lost inadvertently.

Microscopic organisms including protozoa and other parasites, fungi, archaea, bacteria, unicellular algae, viruses and viroids.

An infectious organism, usually microscopic, capable of causing disease in a host.

Any devices or equipment, including clothing, designed to be worn or held by a person on its own, or as part of a system, to protect against one or more health and safety hazards.

Proteinaceous infectious particles that lack nucleic acids, which can cause scrapie and other related neurodegenerative diseases of humans and animals.

A process of estimating the potential of a hazard (source of harm) to give rise to an adverse outcome. This estimation is based on a combination of the likelihood of the hazard occurring and the consequences if the hazard occurs. Control measures are used to limit the risk.

Indicates a statement is mandatory.

Objects or devices having sharp points or protuberances or cutting edges, capable of cutting or piercing the skin.

NOTE: See AS 4031 for information on sharps containers.

Indicates a recommendation.

The state of being free from viable microorganisms.

NOTE: In practice, no such absolute statement regarding the absence of microorganisms can be proven.

A validated process used to render a product free from viable microorganisms.

11NOTE: The number of microorganisms that survive a sterilization process can be expressed in terms of probability. While the probability may be reduced to a very low number, it can never be reduced to zero.

Living: capable of growth even though resuscitation procedures may be required, e.g. when microorganisms are sub-lethally damaged by being frozen, dried, heated or affected by chemicals and disinfectants.

For the purpose of this Standard, the abbreviations below apply:

| AQIS | Australian Quarantine and Inspection Service |

| BC | Biosafety committee |

| BSC | Biological safety cabinet |

| CWA | CEN Workshop Agreement |

| DNA | Deoxyribonucleic acid |

| ERMA | Environmental Risk Management Authority |

| GMO | Genetically modified organism |

| HEPA | High-efficiency particulate air |

| HSNO | Hazardous Substances and New Organisms |

| I AT A | International Air Transport Association |

| IBC | Institutional biosafety committee |

| IBSC | Institutional biological safety committee |

| IMO | International Maritime Organization |

| MAP BNZ | Ministry of Agriculture and Forestry Biosecurity New Zealand |

| NHMRC | National Health and Medical Research Council |

| NRL | National Radiation Laboratory |

| NT AC | National Tuberculosis Advisory Committee |

| OGTR | Office of Gene Technology Regulator |

| OHS | Occupational health and safety |

| PC | Physical containment |

| PPE | Personal protective equipment |

| RPE | Respiratory protective equipment |

Management shall provide staff with a policy statement on laboratory safety that recognizes the special hazards associated with microorganisms.

Research, teaching or operational work with biohazards shall only be undertaken after a risk assessment of the work has been conducted and it has been demonstrated that any hazards are controlled. This process shall be documented and regularly reviewed to ensure its ongoing validity. Review shall be undertaken whenever a change to the parameters of the original risk assessment is planned. See CWA 15793 and AS/NZS ISO 31000.

The risk assessment shall be done prior to commencement of any work to determine the appropriate type and level of containment facility. The risk assessment should include consideration of the following:

All risk assessments that involve biological systems are subject to a level of uncertainty due to a lack of experimental evidence. The level of uncertainty should be considered when conducting the risk assessment.

As an overall principle under occupational health and safety (OHS) laws, the employer is responsible for ensuring that the workplace is safe and free from risks to health.

13Organizational arrangements put in place to meet management responsibilities will depend on—

The central element of such arrangements is a Biosafety Committee (BC). The terms of reference of the BC in relation to biohazards should be as follows:

A safety officer shall be available to provide advice and guidance on microbiological safety.

The supervisor shall ensure that safe procedures are documented and put into practice. The supervisor shall implement initial and continuing training programs, ensure staff are supervised and ensure maintenance is carried out in accordance with safe procedures. The supervisor should also ensure that casual visitors do not have unrestricted access to the laboratory.

All laboratory work shall be carried out with regard to the safety of laboratory occupants. The following requirements apply to all laboratory personnel:

The Australian Quarantine and Inspection Service (AQIS) approves places where post-entry quarantine requirements apply for a wide range of human, plant and animal pathogens and human, plant and animal products, so that it can be sure that these activities are performed with a minimal degree of risk.

14To gain approval as a quarantine approved premises (QAP), there are conditions that the premises must meet to assure AQIS that the risk of any quarantine breach is minimal. These conditions detail the requirements and responsibilities for containment facilities where the premises are utilized for research, analysis or testing of imported material, including microorganisms, animal and human products and soil. Premises of this type include microbiological, animal, plant and invertebrate facilities.

Further information on the approval process for quarantine approved premises is available at http://www.daff.gov.au/aqis/import/general-info/qap.

AQIS will also require institutions to obtain a permit for work conducted in containment facilities. Such permits contain special conditions. The import conditions database (ICON) should be consulted at http://www.aqis.gov.au/icon32/asp/homecontent.asp.

In New Zealand, Ministry of Agriculture and Forestry Biosecurity New Zealand (MAF BNZ) controls the import of biological risk goods, establishes Standards for laboratories receiving and holding such goods and enforces the compliance to those standards.

For further information, contact—

Import Standards Group

MAF BNZ

Box 2526

Wellington New Zealand

Website: www.maf.govt.nz

Under the Commonwealth gene technology legislation, certain dealings with genetically modified organisms (GMOs) are required to be conducted in facilities that meet and are certified as complying with OGTR Guidelines for the certification of physical containment facilities.

Organizations seeking information about the regulatory requirements that apply to work with GMOs should contact the OGTR for further information at the following address:

Office of the Gene Technology Regulator

MDP 54

GPO Box 9848

CANBERRA ACT 2601

Website: www.ogtr.gov.au

Under the Hazardous Substances and New Organisms (HSNO) Act 1996, work with genetically modified organisms is regulated by the Environment Risk Management Authority (ERMA). In general, all work involving the holding or development of GMOs shall be carried out in accordance with controls set by ERMA, or an IBSC or the Chief Executive of ERMA New Zealand in containment facilities approved by MAF BNZ. Work involving GMOs shall be carried out in accordance with MAF BNZ and ERMA New Zealand Standard: Facilities for Microorganisms and Cell Cultures: 2007a.

15Laboratories should consult—

ERMA New Zealand

PO Box 131

Wellington

Email: enquiries@ermanz.govt.nz

Website: www.ermanz.govt.nz

Work involving GMOs shall be carried out in accordance with controls set by HSNO Act Approvals. Such work shall be carried out in MAF-BNZ-approved containment facility to the appropriate Standard.

Laboratory biosecurity, as opposed to laboratory biosafety, refers to the institutional and personal security measures designed to prevent the loss, theft, misuse, diversion or intentional release of pathogens and toxins. Facilities holding pathogens or toxins should prepare and implement a specific laboratory biosecurity program according to the requirements of the facility, the nature of the pathogens(s) or toxins(s), the type of laboratory work conducted and the local conditions. Measures should include a secure inventory of all microorganisms, including such information as location and access. All personnel in such facilities should be trained in biosecurity measures.

NOTE: In Australia, the regulation of security sensitive biological agents (SSBA) is governed by the National Health Security Act 2007 administered by the Commonwealth Department of Health and Ageing (www.health.gov.au/ssba).

On completion of the construction of a containment facility or major changes to a containment facility, the surrounding building, environment, associated air supply or exhaust systems, the facility shall be assessed for overall compliance with this Standard. An itemized checklist should be developed to assist in ensuring all requirements of the Standard relevant to the particular facility are taken into account when conducting the assessment.

All personnel shall be advised of the risk of occupational exposure to microorganisms to which they may not be immune.

When working with human pathogens of Risk Group 3 or Risk Group 4, each person working in the laboratory or animal, plant or invertebrate facility shall be subjected to an initial medical examination, including a chest X-ray where relevant, and periodic examinations. A baseline serum sample should be obtained from at risk personnel and stored for future reference. (See also Clauses 2.6.3 and 2.6.5.)

When working with human pathogens of Risk Group 4, a system shall be set up for reporting accidents and exposures to microorganisms, for monitoring employee absenteeism and for the medical surveillance of illnesses that are potentially laboratory associated.

16Minor cuts and abrasions, which provide routes for infection from contaminated surfaces, should be adequately covered and kept dry. Infections (especially respiratory or wound) can provide sources of contamination for experimental materials and fellow workers. Individual cases should be assessed in relation to the particular laboratory’s work. All injuries that occur in the workplace shall be reported to the supervisor (see Clause 2.7). Immediate medical action is required after human blood or body fluid exposure and contaminated sharps injuries. (See the Department of Health and Ageing publication. Infection control guidelines for the prevention of transmission of infectious diseases in the health care setting.) Consideration should be given to whether any infection was laboratory acquired.

A serum bank can be invaluable when there are questions of work-related infection. Subject to privacy and informed consent considerations, baseline serum samples should be collected from ‘at-risk’ personnel, to be stored for future reference. Additional serum samples may be collected periodically, depending on the risk of exposure to agents handled in the laboratory.

If samples are collected, procedures shall be documented defining who owns the serum, how it is stored, who can access it for testing, who may order tests, who evaluates the tests and who can have access to the results.

For those working with human or zoonotic pathogens, or samples that may contain human or zoonotic pathogens, the latest editions of The Australian Immunisation Handbook published by the NHMRC or the Immunisation Handbook published by the New Zealand Ministry of Health, as appropriate, should be consulted and implemented.

All new staff working with specimens and cultures potentially containing Mycobacterium tuberculosis (TB) complex are recommended to have a tuberculin skin test (TST) or TB gamma-interferon assay. Prior vaccination with Bacille Calmette-Guerin (BCG) confounds TST testing but not the TB gamma interferon assay (see Reference 1.1). Staff with negative test results should be retested on an annual basis (see the NTAC Guidelines for Australian Mycobacteriology Laboratories or Guidelines for Tuberculosis Control in New Zealand 2003, as appropriate).

Vaccination against M. tuberculosis is not generally recommended. However BCG vaccination should be considered for staff with high risk of exposure to TB and as recommended by State/Territory TB control authorities.

Consideration should be given to the immunization of support staff where appropriate.

Persons who are immuno-suppressed, immuno-compromised, or otherwise unduly vulnerable to infection, such as persons who are diabetic, should inform their supervisor or person responsible for microbiological safety of their condition so that appropriate action may be taken. Medical opinion may be required if working with human pathogens. Some microorganisms that are regarded as part of the normal flora of humans or animals may be pathogenic for immuno-compromised persons.

Laboratory management shall inform all female employees of the risk to the unborn child or the pregnant woman of occupational exposure to certain microorganisms (e.g. Toxoplasma gondii, Listeria monocytogenes, cytomegalovirus, parvovirus B19, rubella virus, human immunodeficiency virus (HIV), Coxiella burnetii and hepatitis B, C and E viruses) and some fungi. The precise steps taken for protection will vary, depending on the microorganisms to which the woman may be exposed. Medical opinion may be required.

17Where an incident has occurred resulting in an injury or illness, priority shall be given to the care of the injured or ill person. The project risk assessment should be consulted and consideration should be given to the Risk Group if a microorganism is involved, how it might be transmitted and if any hosts, the environment or processes are at risk as a result of the accident. First aid should be applied by trained personnel, ensuring that they do not risk being infected. If necessary, medical aid should then be sought (see also Clause 2.6.2). The incident should be reported verbally to the supervisor as soon as reasonably possible, documented using the institution’s health and safety report form and referred to the BC or referred as required by the equivalent institutional procedures.

Where an incident occurs with potential for contamination from infectious material, it should be reported verbally to the supervisor as soon as reasonably possible. The incident should be documented once the appropriate clean-up procedure has been implemented. (See Section 9 dealing with spill clean-up.)

Incidents involving genetically modified organisms or quarantine materials resulting in a breach of containment shall be reported to the relevant authorities.

For certain infections, notification of local authorities may be necessary .

Personnel should be encouraged to report all overt exposures or ‘near hits’, so that they may be documented, investigated and, if necessary, procedures changed. This may prevent another or a similar circumstance producing an incident, injury or illness.

NOTE: Appendix B provides an example of an incident/illness reporting form.

An emergency evacuation plan shall be developed in accordance with AS/NZS 2243.1. The plan shall address emergency microbiological issues and shall include minimization of the microbiological risk associated with any emergency evacuation. The plan should take into account the different arrangements for entry and exit associated with the containment level of the facility.

Contingency plans shall be developed for the spillage of microorganisms and breaches of containment caused by the release of microorganisms outside the laboratory through accident, deliberate action, natural disaster, fire, sabotage, theft, or any other event.

A readily accessible first aid kit shall be provided in an unlocked and clearly labelled container. The contents of the kit shall be appropriate to the needs of the laboratory and maintained in a satisfactory condition.

18NOTE: Reference should be made to National, State and Territory legislation for first aid treatment in the workplace.

All work with microorganisms requires the use of standard techniques to minimize risk to people and the environment. Such techniques also maintain the purity of strains of isolates in the laboratory.

Microorganisms vary widely in their ability to infect humans, animals, plants and invertebrates or to spread in the environment. There is obvious, but varied, risk to people from work with microorganisms isolated from or infecting humans. With regard to microorganisms infecting animals, many do not cause human disease, but some zoonotic microorganisms are responsible for serious human infections and can be responsible for serious harm to the economy and the environment.

Some microorganisms that infect arthropods are capable of causing human disease. The arthropods are then said to be vectors of disease, for example, mosquitoes may transmit arboviruses and lice may transmit rickettsiae.

Certain soil microorganisms, while not pathogenic to humans, may cause diseases in plants and be spread to new locations from improper handling or practices. In general, microorganisms from plant and fish diseases rarely infect humans. Certain microorganisms infecting plants or animals are subject to strict quarantine control in Australia and New Zealand, to protect the environment and primary industry.

Certain microorganisms, e.g. Clostridium botidinum, produce small molecules termed toxins that account for their pathogenicity. Some of the microorganisms that produce toxins are listed in Risk Groups 2 and 3. Toxins are also produced by certain plants and animals such as ricin from castor beans and saxitoxin from shell fish. The safety considerations for working with toxins from these sources are not discussed in this Standard.

The basic approach to working with microorganisms is to regard them as potential pathogens and to handle them with standard microbiological techniques which, in the main, protect the environment and the operator and maintain the purity of the strain or isolate.

Microorganisms vary widely in their infectivity. This is partly due to differences in the portal of entry of the organism (e.g. by skin penetration, ingestion, entry via the respiratory tract or entry via the conjunctiva), the physiology of the microorganism, the infectious dose and the ability of the microorganism to overcome intrinsic immune and other defences of the host.

Surveys of the causes of laboratory-acquired infections (see Reference 1.2) have shown that only about 20% of cases followed known accidents with infectious material, the most common being skin penetration accidents, e.g. with a needle and syringe and injury from broken glass. Spillage, mouth pipetting, leakage during centrifugation and bites from infected animals were other causes. Simple precautions can reduce the likelihood of such accidents occurring.

Many of the remaining 80% of infections are believed to be due to inhalation of aerosols that may be produced from common laboratory operations. Such operations include vortexing, sonicating, homogenizing, dropping cultures of high-titre material, blowing out the last few drops in a pipette, removing a needle from a rubber seal, centrifuging, grinding, vigorous shaking or mixing, opening containers of infectious material whose internal pressure may be different from ambient pressure, intranasal inoculation of animals and harvesting of infected tissues from animals and eggs.

19The probability that an aerosol will contain an infectious dose of an organism is broadly related to the concentration (titre) of the organism in the material being handled. The risk is therefore increased when handling bacterial or viral isolates propagated to high titre in culture or in animals, as compared with clinical specimens, food, water and other samples which may contain fewer organisms. Indeed, high titre cultures of some microorganisms (e.g. some arboviruses) may be infectious by the aerosol-respiratory tract route or through broken skin in the laboratory even though in nature they are normally transmitted by insect bite.

Special containment equipment and procedures have been designed to protect laboratory workers from infection with those microorganisms with a ‘track record’ of transmission by the aerosol-respiratory tract route.

Clause 3.2 describes the classification of microorganisms by risk group based, when possible, on past experience with the infectious potential of the microorganism or on microbiologically-informed prudence when a newly-discovered microorganism of uncertain infectious potential has to be handled.

Section 4 provides the principles on which the requirements for containment facilities are based and requirements common to all types of containment laboratories and facilities.

Section 5 sets out the classification of laboratories, physical containment equipment, laboratory design and procedures to be followed when working in laboratories with microorganisms classified at the various risk groups.

Sections 6, 7 and 8 describe the classification of animal, plant and invertebrate facilities, physical containment equipment, facility design and procedures to be followed when working with microorganisms classified at the various risk groups.

Classifications of infectious microorganisms according to degree of risk have been published in the USA, Canada and the UK, together with recommendations for appropriate laboratory facilities for working with them (see References 1.3, 1.4 and 1.5). The World Health Organization (WHO) suggests each country draw up risk groups according to the microorganisms encountered within its boundaries (see Reference 1.6). Unless otherwise stated, references to particular risk groups, e.g. Risk Group 1, refers to human and animal, plant and invertebrate risk groups.

The following classification has been drawn up for microorganisms that are infectious for humans and animals for Australia and New Zealand by modification of the WHO guidelines and is based on the pathogenicity of the agent, the mode of transmission and host range of the agent, the availability of effective preventive measures, and the availability of effective treatment:

The risk grouping of plant infectious microorganisms is primarily concerned with containment of plant pathogens to avoid risk to the environment. Plant pathogens are infectious agents capable of causing disease in plants and include fungi, bacteria, viruses, viroids, rickettsiae, phytoplasmas and nematodes.

Factors considered in relation to the risk from plant infectious microorganisms are—

The following four risk groups are used to manage risks posed by plant infectious microorganisms:

The risks posed by invertebrates are based on the nature of the microorganism that they may be carrying and the nature of the invertebrate itself.

Examples include viruses in mosquitoes, midges and biting flies, Borrelia in soft ticks, trypanosomes in Triatomid bugs, and tospoviruses in thrips.

Factors considered in relation to the risk are—

The following four groups are used to identify the risks posed by infectious microorganisms carried by invertebrates:

Tables 3.1 to 3.8 and 3.9 to 3.11 list examples of microorganisms in Risk Groups 2 to 4 and Plant Risk Groups 2 to 4 respectively. See Clause 3.3.4 in relation to invertebrate risk group examples. The risk group classifications listed in Tables 3.1 to 3.7 are appropriate for small-scale laboratory operations with microorganisms of Risk Groups 2 and 3. Where larger volumes or very high concentrations of the microorganisms are to be handled, the risk of infection or inadvertent release from containment can be higher and additional precautions or an increase in physical containment level may be appropriate. This also applies to situations where the potential to cause environmental and economic damage is a significant concern.

A risk assessment shall be conducted on all microorganisms to determine if the work needs to be conducted with additional precautions or in a higher level of physical containment. The risk assessment should include a review of recent literature to determine if any additional information may warrant changes to the risk grouping or the level of physical containment.

No tables are provided for microorganisms belonging in Risk Group 1, as the number of relevant microorganisms is large.

Tables 3.1 and 3.5 list examples of bacteria of Risk Group 2 and Risk Group 3 respectively and additional information is indicated in footnotes. Currently, no bacteria are classified in Risk Group 4. In addition to the information in the tables, reference should be made to the work practices specified for the relevant level of physical containment.

22Guidelines for Australian Mycobacteriology Laboratories published by the National Tuberculosis Advisory Committee or Guidelines for Tuberculosis Control in New Zealand 2003 published by the Ministry of Health New Zealand, as appropriate, should be consulted for specific requirements for collection, handling and culture of specimens for mycobacteria.

Many parasites are regarded as Risk Group 2, with respect to their infectious stages. Preparations that are known to be free of infectious stages may not require a containment level corresponding to this risk group. Table 3.2 lists examples of Risk Group 2 parasites.

Tables 3.3 and 3.6 list examples of fungi of Risk Group 2 and Risk Group 3 respectively.

Tables 3.4, 3.7 and 3.8 list examples of viruses for Risk Groups 2, 3 and 4 respectively.

The additional containment requirements for poliovirus set out in Appendix C shall be applied.

Tables 3.9, 3.10 and 3.11 list examples of plant pathogens of Plant Risk Groups 2, 3 and 4 respectively.

Invertebrates are able to act as vectors for human, animal and plant disease. Pathogens that use invertebrates as vectors are not listed in separate tables. Instead, examples of pathogens of Risk Groups 2, 3 and 4 that are vectored by invertebrates are included in Tables 3.1, 3.2, 3.4.3.5 and 3.7 to 3.11.

Such specimens would normally be regarded as Risk Group 2 and shall be handled in Physical Containment Level 2 facilities unless a higher risk group is indicated by the clinical notes. This applies in all microbiology and other pathology laboratories, e.g. for haematology and biochemistry. However, if a microorganism of a higher risk group is isolated from a specimen, the isolate and all samples from that source shall be handled according to the corresponding risk group, and at the appropriate physical containment level.

All clinical and diagnostic specimens shall be treated with care as they may contain multiple types of infectious microorganisms. Examples of precautions that should be adopted are provided in the Department of Health and Ageing publication. Infection control guidelines for the prevention of transmission of infectious diseases in the health care setting and NOHSC: 2010.

Cultures and materials containing microorganisms are regularly transferred within and between institutions and PC levels. Laboratory-acquired infections have occurred because of cross-contamination and ineffective attenuation or inactivation.

It is strongly recommended that prior to despatch and upon receipt of ‘pure’ cultures, tests are carried out to ensure purity.

If infectious microorganisms are attenuated or inactivated prior to removal to a lower PC level or prior to transfer between institutions, the attenuation or inactivation processes shall

23be verified. The identity and purity of cultures shall be confirmed before they are transferred to lower containment levels or between institutions.

Routine quality control testing of registered live vaccine strains should be carried out in a BSC.

Work with cells has the potential to be hazardous to laboratory workers and the environment, depending on the source of the cells and the likelihood that they contain infectious microorganisms. In some instances, PCI teaching labs can be adequate if good microbiological practices are followed, e.g. work with standard human cell lines. However, the preparation of primary cells from human organs or tissues shall be conducted in PC2 containment. The manipulation of these cell lines should be done in Class II BSCs. Some cell lines contain Mycoplasma and although they can be ‘cleaned up’, can become reinfected and again pose a hazard to the laboratory worker. Cell lines from an animal source can also contain microorganisms that are capable of causing disease in humans and animals.

Plant cells and tissue cultures can contain plant infectious microorganisms that have the potential to spread in the environment if inadvertently released and cause economic and environmental damage.

A documented risk assessment shall be carried out to determine what level of containment is required for the cells proposed for use.

All cells shall be decontaminated before disposal.

Prions are resistant to most traditional methods of inactivation used for other microorganisms such as formaldehyde, ultraviolet light, ethylene oxide, ionizing radiation and moist heat at 121°C. Because of the difficulties in inactivating the infectivity, these agents pose particular laboratory problems. However, they are not easily spread from host to host and the usual mechanism of spread appears to be by the ingestion or grafting of infectious material. When working with infectious or potentially infectious prions, a laminar flow cytotoxic drug safety cabinet shall be used. Table 3.4 lists examples of prions of Risk Group 2. See also Clauses 10.8 and 12.2.1. Table F2 provides guidance on disinfection of equipment or surfaces contaminated with prions.

24| Organism |

|---|

| Abiotrophia spp. |

| Acidovorax spp. |

| Acinetobacter spp. |

| Actinobacillus spp. |

| Actinomyces spp. |

| Aeromonas hydrophila |

| Afipia spp. |

| Arcanobacterium haemolyticum |

| Bacillus cereus |

| Bartonella henselae, B. quintana, B. vinsonii, B. elizabethiae, B. weisii |

| Bordetella pertussis |

| Borrelia (mammalian) spp. |

| Brucella ovis |

| Brucella spp. serology only |

| Burkholderia spp. (except B. mallei), Burkholderia pseudomalleib,f |

| Campylobacter coli, C. fetus, C. jejuni |

| Capnocytophaga canimorsus |

| Chlamydia spp. (except C. psittaci) |

| Clostridium spp. |

| Corynebacterium diphtheriae, C. renale, C. pseudotuberculosis |

| Coxiella burnetii serology, other tests on samples |

| Dermatophilus congolensis |

| Edwardsiella tarda |

| Eikenella corrodens |

| Enterococcus spp. (Vancomycin-resistant strains) |

| Erysipelothrix rhusiopathiae |

| Pathogenic Escherichia coli (except genetically rippled strainsc) |

| Verocytotoxin-producing Escherichia coli (VTEC)b |

| Fusobacterium spp. |

| Gardnerella vaginalis |

| Gordona spp. |

| Haemophilus influenzae, H. ducreyi |

| Helicobacter pylori |

| Kingella kingae |

| Klebsiella spp. |

| Legionella spp. |

| Leptospira interrogans (all serovars)d |

| Listeria spp., Listeria monocytogenese |

| Moraxella spp. |

| Mycobacterium spp. other than M. tuberculosis complexf |

| Mycobacterium tuberculosis complex (except multi-drug resistant strainsf, g, h) |

| Mycoplasma pneumoniaef |

| Neisseria gonorrhoeae, Unspeciated Neisseriab, f, N.meningitidisb, f |

| Nocardia spp. |

| Oligella spp. |

| Pasteurella spp. |

| Pseudomonas spp. |

| Rhodococcus equi |

| Salmonella serovars |

| Salmonella Paratyphi A and Bb |

| Salmonella Typhib, e |

| Serratia spp. |

| Shigella spp.b |

| Sphaerophorus necrophorus |

| Staphylococcus aureus |

| Stenotrophomonas maltophilia |

| Streptobacillus moniliformis |

| Streptococcus pyogenes, S. pneumoniae |

| Treponema pallidum |

| Ureaplasma ureolyticum |

| Vibrio cholerae, V. parahaemolyticus, V. vulnificus |

| Yersinia spp. (except Y. pestis) |

| a This list is not exhaustive. Some species of some genera may be classified as Risk Group 1 subject to a risk assessment and check of current literature. b Low infectious dose, high pathogenicity, common source of laboratory-acquired infections. c For genetically crippled strains, refer to the gene technology regulations. d Can penetrate intact skin. e May be dangerous for pregnant women. f High risk of aerosol spread. g Vaccination, see Clause 2.6.4. h Less than 5000 cultures per year. See references in Clause 3.3.2.1. |

| Organism |

|---|

| Ancylostoma duodenale |

| Ascaris lurmbricoides |

| Babesia divergens |

| Babesia microti |

| Brugia spp. |

| Clonorchis sinensis |

| Cryptosporidium spp. |

| Echinococcus spp. |

| Entamoeba histolytica |

| Giardia duodenalis (also known as Giardia lamblia and Giardia intestinalis) |

| Hymenolepis diminuta |

| Hymenolepis nana |

| Leishmania (mammalian) spp. |

| Loa loa |

| Naegleria fowleri |

| Necator americanus |

| Opisthorchis spp. |

| Plasmodium (human and simian) |

| Strongyloides stercoralisb |

| Taenia saginata |

| Taenia soliumc |

| Toxocara canis |

| Toxoplasma gondiid |

| Trichinella spiralis |

| Trypanosoma brucei subspp. |

| Trypanosoma cruzi |

| Wuchereria bancrofti |

| a This list is not exhaustive. b Filariform larvae may cross intact skin. c Accidental ingestion of eggs may lead to cysticercosis d May be teratogenic |

| Organism |

|---|

| Aspergillus fumigatus and A. flavus |

| Candida albicans |

| Cladophialaphora spp. |

| Cryptococcus gattii |

| Cryptococcus neoformans |

| Epidermophyton floccosam |

| Microsporum spp. |

| Scedosporium spp. |

| Sporolhrix schenckii |

| Trichophyton spp. |

| a This list is not exhaustive. |

| Virus or prion |

|---|

Adenoviridae

|

Arenaviridae

|

Caliciviridae

|

Coronaviridae

|

Flaviviridae

|

Hepadnaviridae

|

Herpesviridae

|

Orthomyxoviridae

|

Paramyxoviridae

|

Parvoviridae

|

Picornaviridae

|

Poxviridae

|

Prions

|

Reoviridae

|

Retroviridae (serology, other tests on samples)

|

Togaviridae

|

Unclassified

|

| a This list is not exhaustive. b While these agents are exotic to Australia, the AQIS permit determines the level of containment required. c Vaccination available, see Clause 2.6.4. d May be teratogenic. e See also Tables 3.7. f May be dangerous for pregnant women. NOTE: Hepatitis G and hepatitis TT have been excluded from this Table as there is insufficient evidence that these agents are associated with disease. |

| Organism |

|---|

| Bacillus anthracis |

| Bartonella bacilliformis |

| Burkholderia mallei |

| Brucella spp. (except serology (see Table 3.1) and B. ovis) |

| Chlamydia psittaci |

| Coxiella burnetii (cultures, animal work and concentrates)b,c |

| Francisella tularensis (type A) |

| Mycobacterium tuberculosis complexc,d,e |

| Rickettsia spp. |

| Yersinia pestis |

| a This list is not exhaustive. b May be dangerous for pregnant women. c Vaccination, see Clause 2.6.4. d Respiratory protection should be considered. e Greater than 5000 cultures per year, susceptibility testing, known multi-drug resistant strains. See references in Clause 3.3.2.1. |

| Organism |

|---|

| Blastomyces dermatitidis |

| Coccidioides immitisb |

| Coccidioides posadasii |

| Histoplasma spp. |

| Paracoccidioides brasiliensis |

| Penicillium marneffei |

| a This list is not exhaustive. b May be dangerous for pregnant women. NOTE: The mycelial forms of these fungi produce highly infectious conidia. The use of plate cultures should be avoided. |

| Virus |

|---|

Arenaviridae

|

Bunyaviridae

|

Coronaviridae

|

Flaviviridae

|

Orthomyxoviridae

|

Paramyxoviridae

|

Retroviridae (from cultures and concentrates)

|

Rhabdoviridae

|

Togaviridae

|

| a This list is not exhaustive. b Animal inoculations to be performed under PC4 containment. c While these agents are exotic in Australia, the AQIS permit determines the level of containment required. d Vaccination available, see Clause 2.6.4. |

| Virus |

|---|

Arenaviridae

|

Bunyaviridae

|

Filoviridae

|

Flaviviridae

|

Herpesviridae

|

Paramyxoviridae

|

| a This list is not exhaustive. b Although only a few cases of infection with Hendra have occurred, the death rate has been high. It is considered appropriate to include this virus in Risk Group 4 from the limited information available. |

| Organism |

|---|

| Grapevine fan leaf nepovirus |

| Asparagus stem blight (Phomopsis asparagi) |

| Tomato yellow leaf curl virus |

| Citrus tristeza virus |

| Onion smut (Urocystis cepulae) |

| Lettuce leaf blight (Pythium tracheiphilum) |

| a This list is not exhaustive. |

| Organism |

|---|

| Citrus canker (Xanthomonas axonopodis) |

| Fire blight (Erwinia amylovora) |

| Plum pox potyvirus |

| Potato cyst nematode (Globodera pallida) |

| Pierce’s disease (Xylella fastidiosa) |

| Chestnut blight (Cryphonectria parasitica) |

| Pine pitch canker (Fusarium circinatum) |

| a This list is not exhaustive. |

| Organism |

|---|

| Guava rust (Puccinia psidii) |

| Karnal bunt (Tilletia indica) |

| Sudden oak death (Phytophthora ramorum) |

| Potato leaf blight (Phytophthora infestans exotic strains) |

| Grapevine rust (Phakopsora euvitis) |

| a This list is not exhaustive. |

Containment of microorganisms involves a combination of buildings, engineering function, equipment, and worker practices to handle microorganisms safely. Physical containment is the term used to describe procedures and structures designed to reduce or prevent the release of viable organisms into the outside environment. Four PC levels, PC1 to PC4. are assigned for work with microorganisms.

Viable microorganisms and animals, plants or invertebrates inoculated with microorganisms from defined risk groups shall be used, stored or housed in corresponding or higher level containment facilities.

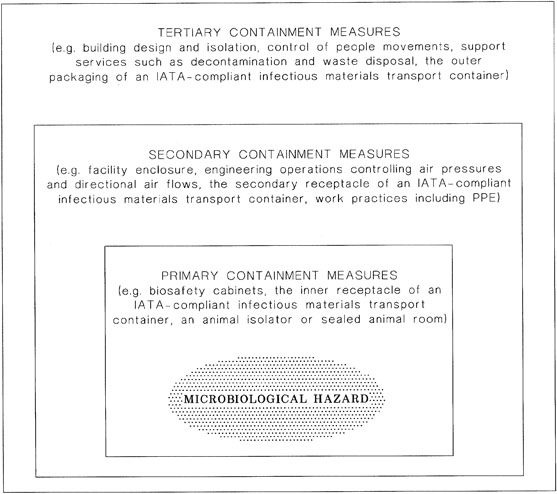

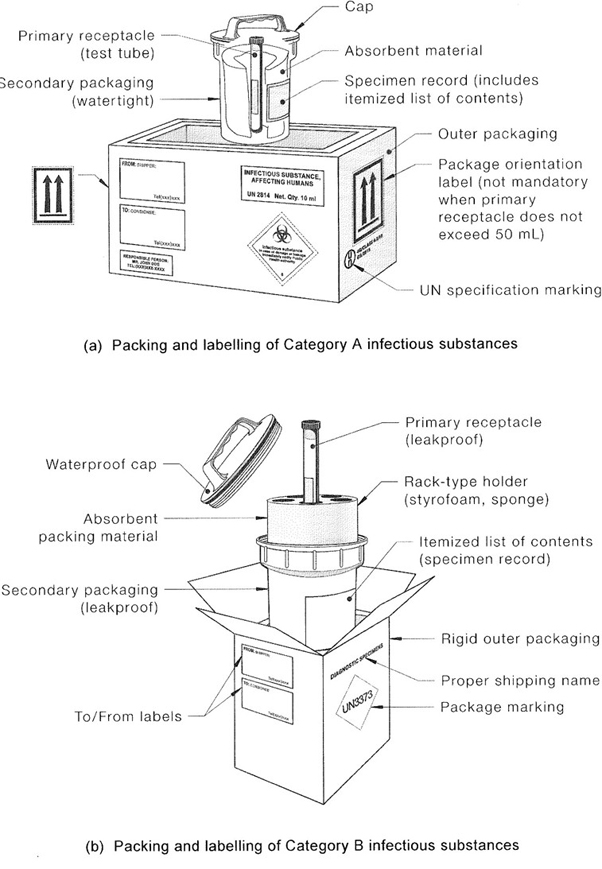

The three general descriptors by which microbiological containment is achieved are known as primary, secondary and tertiary containment measures. Optimal microbiological containment is provided by the ‘box-within-a-box’ principle (see Figure 1), where the highest hazards are enclosed by multiple containment measures.

Primary containment measures are the constraints immediately surrounding the source of infectious material, such as a BSC, a ventilated animal enclosure, a sealed animal room with appropriate air pressure controls, or the leakproof container forming the inner receptacle of an approved I ATA infectious materials transport container. Invariably, there is a primary barrier or other containment measure restricting the passage of infectious microorganisms.

Secondary containment measures include the design of a laboratory or device that encloses the primary containment. Facility design and engineering operations providing laboratories with air pressure control and directional air flow (supplemented by HEPA filtration of exhaust air) are examples of secondary containment measures. Another example is the secondary receptacle of an approved I ATA transport container. In the laboratory or animal room, secondary physical containment measures are invariably supplemented by defined work practices, including PPE.

Tertiary containment measures provide protection of the wider environment by supporting the secondary containment, e.g. using the outer packaging of an approved IATA transport container, an isolated building complex, control of people movements, and provision of support services such as decontamination and laundering of clothing and disposal of infectious wastes.

35The hazard and risk posed by different microorganisms varies greatly and this is reflected by the organization of microorganisms into the risk groups described in Section 3. The physical containment level used when working with microorganisms shall be at least the appropriate level for the risk group of the microorganism, i.e. Physical Containment Level 1 for Risk Group 1, Physical Containment Level 2 for Risk Group 2. Unless otherwise stated, Risk Group 1 to Risk Group 4 mean human and animal, plant and invertebrate Risk Group 1 to Risk Group 4 and PC 1 to PC4 mean laboratory, animal, plant and invertebrate PC 1 to PC4.

All work done in a laboratory or facility of a specific level shall follow procedures prescribed for that level of physical containment.

Section 5 details the appropriate requirements and recommendations for four physical containment levels of laboratories corresponding to Risk Groups 1 to 4 defined in Clause 3.2.2 and include the laboratory structural requirements and facilities, PPE, safety equipment, practices, techniques and health monitoring procedures. The four classifications of laboratories are defined by the physical containment prefix ‘PC’.

Sections 6, 7 and 8 contain the corresponding requirements for animal, plant and invertebrate facilities. The corresponding classifications for animal, plant and invertebrate facilities have ‘Animal’, ‘Plant’ or ‘Invertebrate’ preceding ‘PC’, as appropriate.

A PC1 laboratory or facility is suitable for work with microorganisms where the hazard levels are low, and where laboratory or facility personnel can be adequately protected by standard laboratory practice. This level of laboratory or facility with its practices and equipment is usually suitable for student and undergraduate teaching laboratories. The organisms used should generally be classified as Risk Group 1. Specimens that have been inactivated or fixed may be handled in PC 1 facilities.

This level of laboratory or facility with its practices and equipment is applicable to research, diagnostic and other premises where work is carried out with microorganisms or material likely to contain microorganisms that are classified as Risk Group 2 microorganisms. If working with specimens containing microorganisms transmissible by the respiratory route or if the work produces a significant risk to humans or the environment from the production of infectious aerosols, a biological safety cabinet shall be used.

This level of laboratory or facility with its practices and equipment is applicable to research, diagnostic and other premises where work is carried out with microorganisms or material likely to contain microorganisms that are classified as Risk Group 3 microorganisms.

A PC3 laboratory or facility provides additional building features and services to minimize the risk of infection to individuals, the community and the environment.

This level of laboratory or facility with its practices and equipment is applicable to work with microorganisms classified as Risk Group 4 microorganisms.

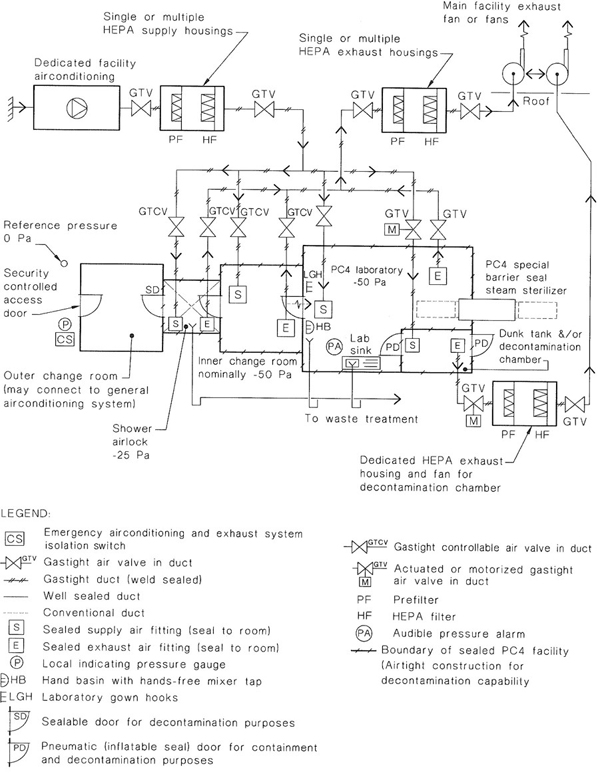

36A PC4 laboratory or facility is situated in a building separate from other laboratories or facilities or constructed as an isolated area within a building. The facility is maintained under negative pressure and includes secondary barriers such as sealable openings, airlocks or liquid disinfection barriers, a clothing-change and shower room contiguous to the laboratory or facility ventilation system, and exhaust air and liquid waste decontamination systems to prevent the escape of microorganisms to the environment.

A PC4 laboratory or facility may be of two types; one where work is conducted in a Class III biological safety cabinet exhausting outside the facility or one where the work is conducted without being isolated in such a manner and staff wear fully encapsulated positive pressure suits.

The design of the facility shall take into account the potential impact of severe environ mental and climatic events (such as seismic events, flooding, snow, wind storms, fire, cyclones and hail storms) that are likely to occur in the area in which it is located so that the risk of damage to the containment barrier is minimized.

FIGURE 1 RELATIONSHIP BETWEEN CONTAINMENT MEASURES

37The physical containment level used when working with microorganisms in laboratories shall be at least the appropriate level for the risk group of the microorganism, as set out in Section 4. Requirements for laboratory PC1, PC2, PC3 and PC4 containment facilities are set out in Clauses 5.2, 5.3, 5.4 and 5.5 respectively.

All work done in a laboratory of a specific level shall follow procedures prescribed for that level of physical containment.

A Laboratory PC1 facility, in which laboratory personnel can be adequately protected by standard laboratory practice and no containment equipment is required, is suitable for work with microorganisms in Risk Group 1. Specimens that have been inactivated or fixed may be handled in a PC1 laboratory.

This level of facility with its practices and equipment is appropriate for student and undergraduate teaching laboratories. Work may be carried out on the open bench.

A sign complying with Appendix D showing the level of containment, together with hazard symbols as appropriate and any access restrictions should be prominently displayed at the entrance.

Laboratory facilities shall be constructed in accordance with AS/NZS 2982.1 and the following requirements to facilitate microbiological safety and reduce the likelihood of microorganisms escaping from containment:

Laboratory personnel shall observe the work practices in AS/NZS 2243.1 as well as the following (see also Clause 2.1.6):

NOTE: This includes offices within the containment facility boundary.

Protective clothing to afford protection to the front part of the body shall be worn within the laboratory.

NOTE: A rear-fastening gown is preferable.

NOTE: Disposable loops may be used as an alternative.

NOTES:

A Laboratory PC2 facility is suitable for work with microorganisms in Risk Group 2 and incorporates all the requirements of a Laboratory PC 1 facility with additional requirements relating to conditions of access, safety equipment and staff training requirements. With good microbiological techniques, work with these microorganisms may be carried out on the open bench. If working with specimens containing microorganisms transmissible by the respiratory route or if the work produces a significant risk from the production of infectious aerosols, a biological safety cabinet shall be used.

Institutions with large areas such as entire floors, multiple floors or multiple buildings designated as PC2 areas shall ensure that safety is maintained for both laboratory workers and non-laboratory persons. There is a need to restrict access to the PC2 areas, including via lifts and stairs, preventing the use of laboratories as thoroughfares and ensuring that eating and drinking is prohibited in the entire PC2 area.

Where lifts operate through multiple PC2 levels, the lift itself shall not be classified as PC2 as it may be used by non-laboratory persons. The lift shaft and lift motor areas are required to be accessed by lift technicians and cannot be readily decontaminated. Where it is required to use the lift to transport infectious materials from one floor to another, e.g. to a pressure steam sterilizer on another floor, the infectious materials shall be either double-bagged, the outer bag of which should be sealed during transport, or placed in a secondary sealable, unbreakable container for the transport.

Potentially contaminated laboratory gowns and gloves shall not be worn in lifts.

Inward air flow to the PC2 areas from lifts and lift shafts shall be maintained. This requires attention to cater for the pressure fluctuations and air movements caused by movement of the lift car in the shaft (‘piston effect’).

Where lift equipment is accessed via PC2 areas, care shall be taken to ensure that lift maintenance personnel are able to perform their work without compromising safety or containment.

Stairs that connect only to PC2 areas may be classified as PC2 spaces provided that they satisfy the PC2 construction requirements. Users shall be made aware that wearing potentially contaminated laboratory gowns and gloves in stairs can be a source of cross-contamination. Infectious materials shall be double-bagged, the outer bag of which should be sealed during transport, or placed in a secondary sealable, unbreakable container for transport.

Where large areas are classified as PC2, including associated write-up areas, the prohibition of eating and drinking applies in these adjacent areas. See also Clause 5.3.3(i).

40In addition to the construction requirements specified for PC1 laboratories in Clause 5.2.2, the following shall apply:

NOTES:

NOTE: Structural joints should be minimized in containment laboratories.

NOTE: Where large spaces, such as ceiling voids, are used as part of return or exhaust air paths, care should be taken by personnel accessing such spaces due to the potential for long term build-up of laboratory dust.

NOTE: The pressure steam sterilizer should be as close to the laboratory as possible.

NOTE: Gowns should be hung or stored individually to prevent cross-contamination or contamination of the inside of gowns.

NOTE: Implementation of the second option will generally preclude the use of tiled ceilings for such laboratories.

41NOTE: Where freezers or refrigerators are used by multiple personnel, it is recommended that the names and telephone numbers of the users are displayed on the front of the unit.

An inward flow of air shall be maintained by forced extraction of laboratory air to minimize the spread of aerosols in the event of an inadvertent spill. Recirculation is permitted but not into areas outside the PC2 facility.

Recirculated air shall be filtered to remove airborne particulates. Where long term build-up of particulate material can be hazardous to personnel, filtration should occur before air leaves the laboratory, i.e. at or below ceiling level.

Ventilation system components such as filters and filter plenums can accumulate particulates. Any special precautions that are required for maintenance personnel should be noted at points of access to this equipment.

Ventilation air shall not be directed towards doors or located in positions that can disturb air flow at BSCs.

NOTE: A risk assessment should be conducted to determine the duration of operating hours of the ventilation system based on the active work hours and the ongoing use of equipment such as incubators, water baths and warm rooms.

A Class I or II biological safety cabinet (see Clause 10.7) shall be provided if work with microorganisms transmissible by the respiratory route or work producing a significant risk from aerosol production is anticipated.

Installation and use, including the decontamination of the biological safety cabinet, shall be performed in accordance with the requirements of AS/NZS 2647.

A laminar flow cytotoxic drug safety cabinet (see also Clause 10.8) shall be provided if work involving prions is intended.

Installation and use, including the decontamination of the safety cabinet shall be performed in accordance with the requirements of AS 2639.

When infectious materials are used, a centrifuge fitted with either sealed rotors or sealed buckets shall be used. (See also Clause 10.3.)

In addition to the work practices described in Clause 5.2.3 for PC1 laboratories, the following work practices shall be observed:

NOTES:

NOTE: Large items of equipment can interfere with the airflow pattern in a Class II BSC and correct operation of the cabinet should be validated with the equipment in situ. See Clause 10.3.1.

NOTE: This has been a common cause of laboratory acquired infections.

NOTE: Thermal decontamination of pipettes that are not fully immersed in a liquid, i.e. are empty, can only be achieved in a pre-vacuum steam sterilizer.

43NOTES:

NOTE: Appendix F provides information on disinfectants.

A Laboratory PC3 facility is suitable for work with infectious microorganisms in Risk Group 3 and incorporates all equipment and practices for Physical Containment Levels 1 (Clause 5.2) and 2 (Clause 5.3); however, additional conditions of access, safety equipment and staff training apply.

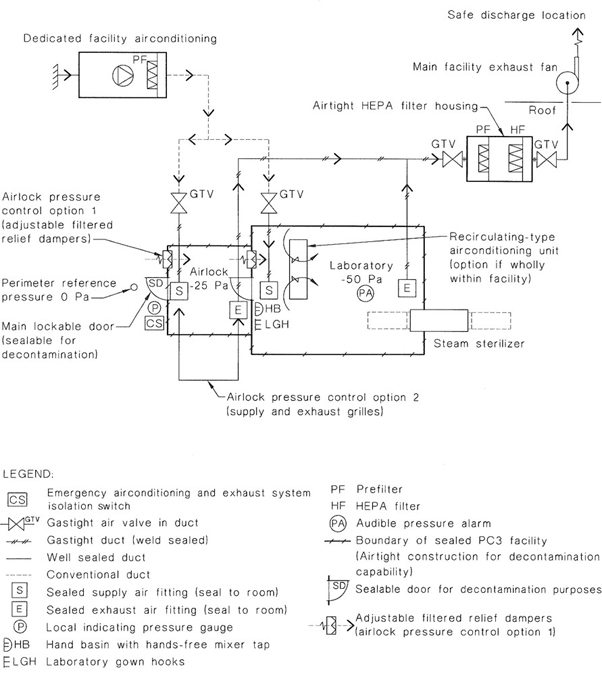

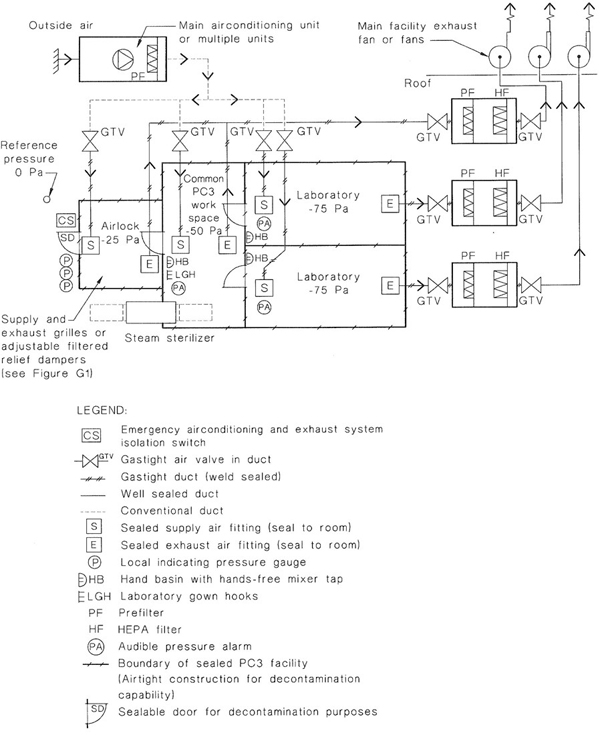

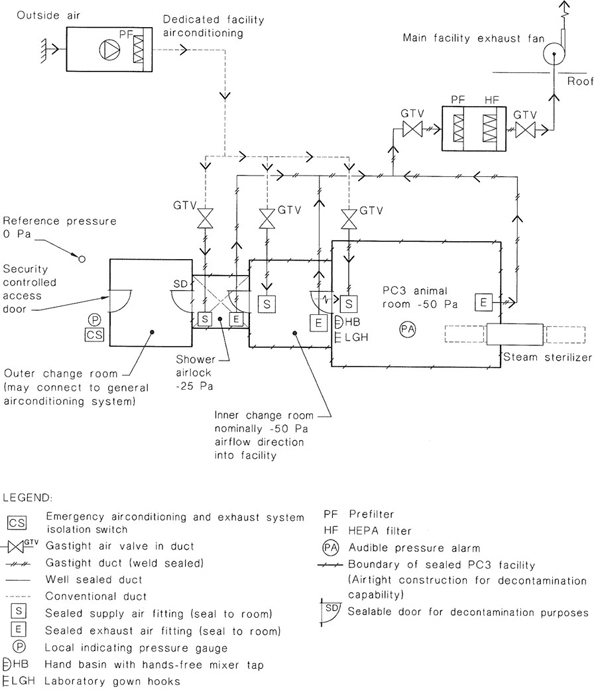

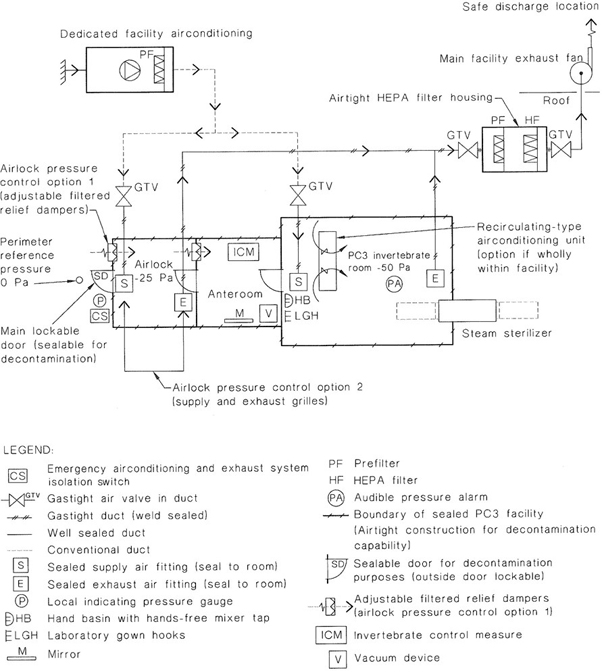

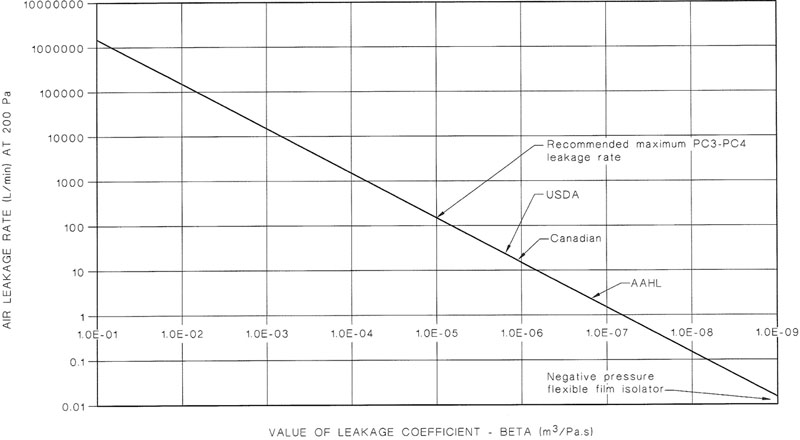

NOTE: The design of a PC3 facility is complex and those planning its construction should seek specialized advice. See also Appendix G for examples of recommended layouts for PC3 facilities showing the design principles involved and Appendix H for airtightness considerations.

In addition to construction requirements described for PC 1 and PC2 in Clauses 5.2.2 and 5.3.3, the following shall apply:

NOTES:

NOTE: Examples of suitable mechanisms include entry and egress ‘traffic light’ alarm systems, door interlock control systems or viewing panels if suitable.

NOTE: Examples of suitable arrangements are the viewing panels in doors required in Item (e) if they allow adequate viewing of laboratory occupants, viewing panels in walls or electronic visual monitoring facilities (e.g. viewing cameras or closed circuit television).

NOTES:

NOTE: The design of the facility should avoid inaccessible spaces. See Appendix H for recommendations on design for airtightness and periodical retesting.

NOTE: See Appendix H.

Some institutions have PC3 facilities consisting of several laboratories within the negative pressure area.

Additional safety structures that may be incorporated into the barrier wall include a dunk tank for removal of containers and materials that can withstand immersion in liquid disinfectant, a decontamination chamber for gaseous decontamination or introduction of large items of equipment and a pass-through box for entry of materials into the facility.

A ventilation system that establishes a negative pressure in the laboratory shall be provided so that there is a directional airflow into the working area. Where laboratories have supply air systems, the supply air and exhaust air systems shall be interlocked, to ensure inward airflow at all times. The proper directional airflow into the laboratory shall be verified by airflow tests. The laboratory (including the airlock) shall be structurally designed to take account of the operation under negative pressures.

Failure of a single component, such as an exhaust fan or a supply fan, can result in extremely high positive or negative pressures in the laboratory. Alarms and failure mode operations of ventilation systems shall address this risk to ensure that interlocks operate rapidly to stop systems. The laboratory shall be constructed to withstand, without cracking or deterioration, the maximum positive and negative pressures that can be generated until failure mode safeguards operate. Automatic and manual failure mode sequences shall be independent of any automated control system that may, itself, be the primary cause of a failure situation.

All air that leaves the laboratory shall be exhausted in accordance with the requirements of this Clause.

Air may be recirculated within each laboratory. If air is recirculated, this shall be achieved utilizing internally-mounted airconditioning equipment such as fan coil units and split system airconditioning units. Any internally-mounted equipment shall be provided with removable panels as required to ensure the complete penetration of gas or vapour during room decontamination.

NOTES:

Ventilation equipment and outlets shall be located to minimize the disturbance to the open faces of Class I and Class II biological safety cabinets.

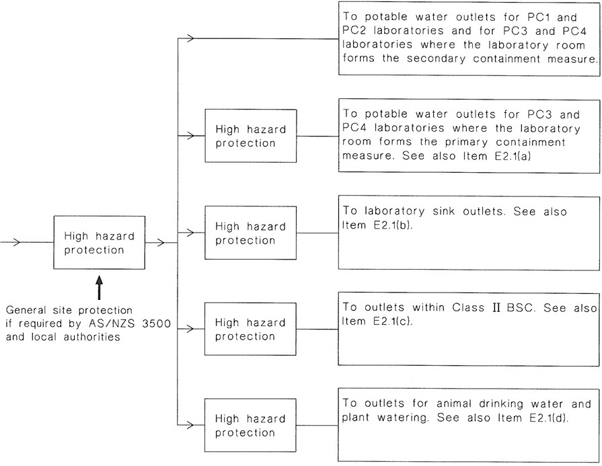

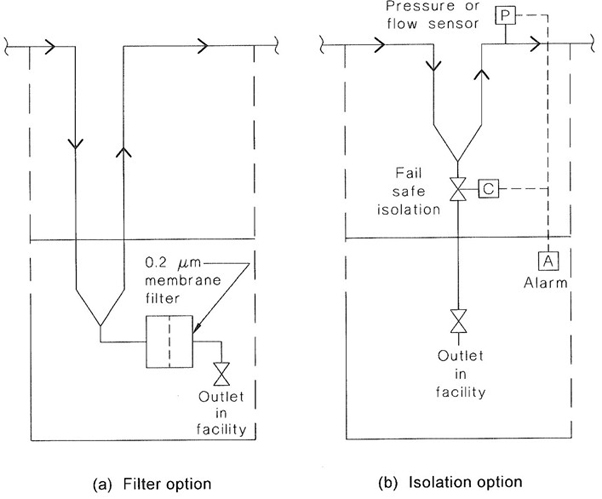

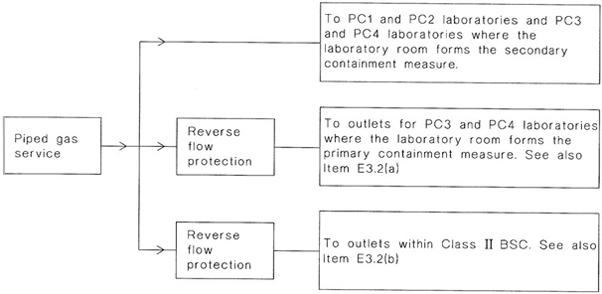

The laboratory ventilation shall incorporate the following features:

NOTE: Additional precautions should be considered when one or more surfaces are external and exposed to fluctuations of pressure due to wind effect. Suitable precautions include the use of an interstitial space that can be maintained at the zero reference pressure and the use of solid walls such as concrete with minimal joints, which are unlikely to be perforated or leak.